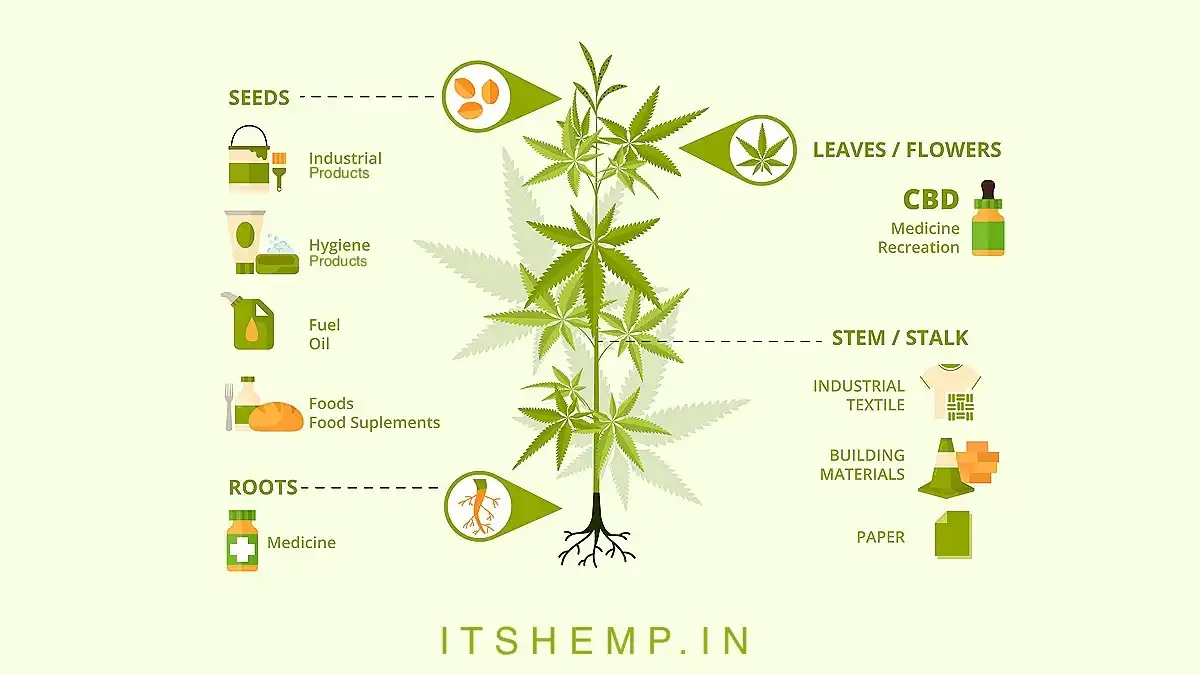

industrial hemp products represent the greatest agricultural opportunity for the mankind. Hemp is a versatile plant offering thousands of pan-industry applications. We can ask ourselves how many hemp varieties are there and how many products can Hemp make, and we’ll be in awe.

From nutritional applications to fashion, textiles, fuels, and plastic replacement, the possibilities of the crop are expanding as we learn more about it. Industrial hemp can disrupt the agricultural medical, health care, pharmaceutical, energy, and tech industries.

Hemp Varieties

Hemp has assorted varieties and strains. Different varieties of hemp perform differently under different environmental conditions. Some varieties serve medicinal purposes while others are better for creating biomass or textiles.

Traditionally, industrial hemp has three main categories:

- Fibre

- Grain

- High-Cannabinoid producing

Fibre Hemp Varieties

Fibre hemp varieties produce long fibres and biomass. How many products can fibre hemp make? These hemp varieties find applications in building materials, textiles, composites, pulp/paper, and fuel industries.

The hemp fibre cultivars are slender, ranging from 10 feet to 18 feet in height. The cultivation and harvest of these varieties are for bast fibre and hurd. Both these parts have great potential in fabric, construction, and some manufacturing operations.

Fibre varieties of hemp require processes and infrastructure that can support large scale harvesting, transportation, and processing.

This is because hemp bales are voluminous and ideally require processing facilities in proximity to the grows.

Grain Hemp Varieties

These hemp varieties are employable primarily for food and nutritional applications. This is because of their high fibre, protein, and fatty acid content.

How many products do grain hemp varieties make?

Traditionally, these varieties yield lower cannabinoid content. Grain hemp seeds have thin walls and are fragile. And thus, require careful handling during processing and transportation.

With grain crops, it is imperative to conduct proper harvesting, processing, transportation, and storage processes to ensure the optimal value for the harvested grain.

Cannabinoid Hemp Varieties

These are currently the most productive hemp varieties. However, they can present regulatory challenges according to the end product that is produced from them.

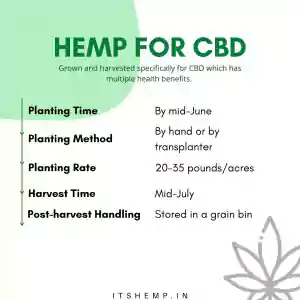

Hemp contains a molecule called Cannabidiol (CBD). It has a varied range of applications as pharmaceutical, nutraceutical, and/or dietary supplements.

The regulation of CBD varies from region to region. High cannabinoids varieties generally grow as only as female plants.

This is because the combination of male and female plants leads to seed production and alleviates cannabinoid yield.

Cultivating Hemp Varieties

As we know, cultivation of hemp varieties can be both for seeds and for psychoactive substances. But among the main products of hemp is bast fibre. Traditionally, bast fibres were used for making ropes, twines, hand-wearing fabrics, and bags. In recent times, the potential applications of the bast fibre have widened. In addition, we can use bast fibres in the production of speciality paper. Some studies evaluate the possibility of using the entire stem to produce paper pulp.

In addition, a promising destination for hemp bast fibres is the production of insulating products and fibre-reinforced composites.

That is not to say that the cultivation of hemp for seeds and psychoactive substances is not prevalent. Cultivated hemp seeds were most commonly used as animal seeds. In recent times, multiple food and industrial applications of hemp are emerging.

Fun Fact: Hemp seeds are healthier than flax and chia seeds and have more nutritional valie. A 100g serving of hemp seeds can serve as much as 64% of our daily nutritional value.

The CBD industry continues to grow drastically. The extraction of CBD oil for numerous health benefits is gaining traction. And oil extracted from the seeds is gaining popularity as a cosmetic and skincare supplement.

Harvesting Hemp Varieties

The harvesting of hemp varieties takes different shapes according to the end use of the crop. Each end-use of the crop calls for different cultivation practices. For instance, the cultivation techniques vary greatly when hemp cultivation is for long fibre bundles than for seeds and fibre.

Hemp harvesting, in the present time, follows two prime ways:

- Longitudinal Hemp Harvesting

- Disordered Hemp Harvesting

Longitudinal Hemp Harvesting

The main products traditional hemp cultivation yields are parallel fibre bundles. We commonly call them long hemp. These can make yarn by the process of wet spinning. For this, harvesters mimic the operation of creating stem hoods. In earlier times, harvesters carried out this process by hand. A reaper and binder cuts the stem in a single passage, ties them into bunches, and drops them on the field where manual labour arranges them for efficient drying. After drying, common flax balers bale the stems.

Disordered Hemp Harvesting

Increasing technical applications of bast fibres led to the development of modern techniques. Their aim was to enable an improved supply of raw material w.r.t to the quality requirement of the successive processor.

The most common technique to achieve this is based on the principle of a one-knife cutting drum. We mount this system onto tractors with a rear driving system. There is a header and an adapted one-knife cutting drum with mass balancing. The hemp stalks are lengthwise fed into the chopping drum. They are cut into 600-700 mm long pieces. Then, placed onto the field directly under the drum.

Multiple field experiments have shown that this method enables adequate retting and drying behaviour of the mowed and cut plant.

Further Advancements in Harvesting Hemp Varieties

One more idea behind harvesting hemp varieties was to preserve the original array of the plant until it gives 600-700 mm long pieces. After it has been cut, eccentric steered conveyor elements snatch up the hemp stalks in a vertical position. Several cutting discs are located at fixed positions. These chop the upright stalks multiple times before laying them on the ground. This harvesting system is suitable for all field and weather conditions because the cutting discs can be interchanged.

In addition, the simple cutters developed into multi-level cutters to cut hemp into shorter pieces.

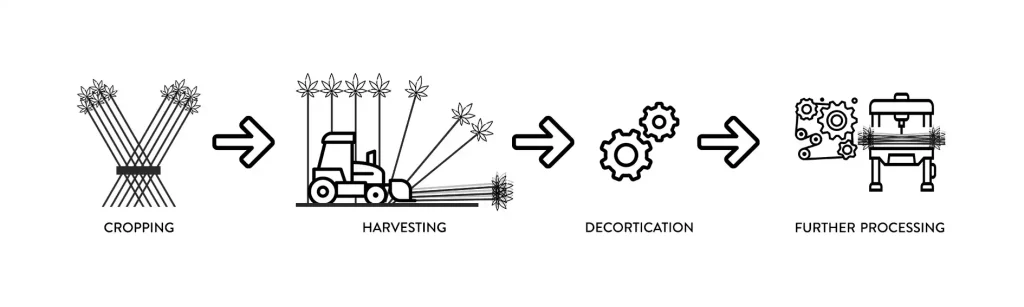

Processing Hemp Varieties

Industrial factories process hemp varieties through two main processing routes. Longitudinal hemp for clothing textiles. This comes from processing lines which always keep the fire bundles aligned to avoid tangle. This ensures maximum fibre yield. Old hemp processing lines are still available in parts of Eastern Europe. These scutch entire stems and yield hemp fibre bundles that are as long as the stems. For processing, short hemp crops or to cut hemp stems to an appropriate size, flax scotching lines can be employed.

As for disordered hemp, since their fibres and fibre bundles have no preferred orientation, multiple processing lines have been developed.

Retting

Irrespective of the processing route, hemp stems of fibre bundles have to go through the process of retting.

Retting is a process of employing the action of microorganisms and moisture on plants to dissolve or rot away much of the cellular tissues and pecins surrounding bast-fibre bundles.

This process facilitates the separation of the bark from the core and loosens the binds between single fibres. This is to ensure that after the extraction process, we get cleaner and finer fibre bundles.

Water Retting

Traditionally, hemp varieties are retted by soaking them in ponds and rivers to produce high-quality fibre bundles. The water penetrates to the central stalk portion and swells the inner cells. These burst the outermost layer and increase the absorption of both moisture and decay-producing bacteria. In the process of water retting, harvesters observe the retting time carefully. Under-retting makes the separation harder and over-retting results in weakened fibre.

Natural water retting uses stagnant or slow-moving waters (ponds, slow streams, and rivers). Stones and woods weigh down bundles of hemp stalk for approximately 8 to 14 days. This time duration depends on the temperature and mineral content of the water.

Dew Retting

More modern techniques for retting hemp fibre bundles include dew retting. This method is popular in areas with limited water resources. In dew retting, the process is to evenly spread plant stalks in grassy fields. The mutual action of sun, bacteria, air, and dewdrops leads to fermentation. The fermentation dissolves much of the stem material around the fibre bundles.

The fibres are separated usually within 2 or 3 weeks. Dew-retted fibre is darker in colour and poorer in quality than water-retted fibre.

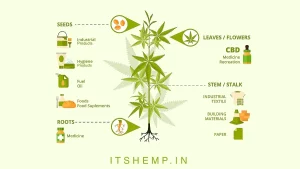

How many products can Hemp make?

This is where hemp gets interesting. The crop can make a variety of commercial and industrial products. Hemp’s applications spread across food, fibre, building material, jewellery, paper, plastic, hemp concrete, biofuels, and more. In this section, we’ll take a brief look at how many products can hemp make.

Hemp Concrete

More commonly known as Hempcrete, hemp concrete is a bio-composite material. It uses the inner woody core of the hemp stalk to produce a mineral matrix. This forms a non-toxic, carbon-negative, and energy-efficient building material. Hempcrete is one of the most sustainable construction materials available today. Mixing lime and water to hemp stalks gives concrete-like blocks. The silica content in the stalks binds with lime and results in a lightweight cementitious insulating material.

Hemp concrete is not a structural element but only an insulating infill between the frame members. The first use of hempcrete was witnessed in 1986 in France when Charles Rasetti renovated the Maison de la Turquie.

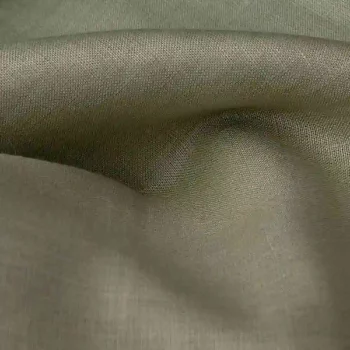

Hemp Clothing

Hemp fibre can be spun into fabric which is used to create a wide range of clothing and home decor items. As a matter of fact, hemp fashion is paving the way for sustainable and slow fashion in India. Hemp fabric is more breathable, durable, and stronger than cotton fabric. It retains body temperature and can be used effectively both in the summers and winters.

Hemp can also be made into denim and leather—providing a sustainable and cruelty-free alternative for a huge aspect of the fashion industry.

-

Hemp House All Natural Hemp Men’s Tshirt₹1,599.00

-

Ecentric beige colour slim fit hemp long kurta₹2,399.00

-

The Hemp Studio Taima Hemp Fabric, Mint Green₹800.00

-

Cannabie Hemp T-shirt You’re Dope Print, Black₹1,299.00

-

Product on saleBhangola Hemp Shoes – प्रथम, Biege ColourOriginal price was: ₹3,299.00.₹1,849.00Current price is: ₹1,849.00.

-

The Hemp Studio Canhamo Hemp Fabric, Pista₹890.00

-

Cannabie Hemp T-shirt Dope Chakra Printed, Black₹1,299.00

-

Cannabie Hemp T-shirt Glitch Print, White₹1,299.00

-

Ecentric Women’s beige colour solid high low lounge wear top₹1,499.00

-

The Hemp Studio Cannabus Hemp Fabric, Herringbone Natural₹1,020.00

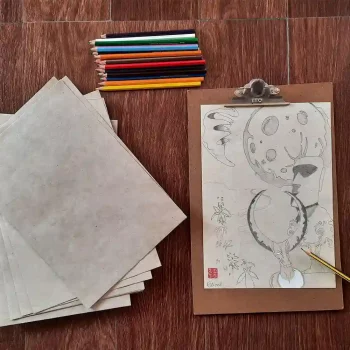

Hemp Paper

Hemp Paper contains exclusively or to a large extent, pulp obtained from fibres of industrial hemp. Compared to wood pulp, hemp pulp offers four times longer fibre, a considerably lower lignin fraction, and high tear resistance and tensile strength.

The main products made from hemp paper are speciality papers such as banknotes, cigarette paper, and technical filter paper. Hemp paper is 4-5 times costlier to produce than wood paper. It is one of the main reasons why we do not use hemp paper for mass applications such as printing and packaging paper.

-

Product on saleBhangola Hemp Notebook (50 Pages, A6)Original price was: ₹499.00.₹349.00Current price is: ₹349.00.

-

B.E Hemp 100% Hemp A4 Unbleached Hemp Paper₹200.00 – ₹650.00

-

OG A5 250GSM LightGreen (Set of 15)₹217.00

-

OG A5 250GSM Indigo (Set of 15)₹217.00

-

OG A5 250GSM DarkGreen (Set of 15)₹217.00

-

OG A5 250GSM Red (Set of 15)₹217.00

-

OG A5 250GSM Yellow (Set of 15)₹217.00

-

OG A5 300GSM White (Set of 50)₹937.00

-

OG A5 300GSM White Sheet (Set of 25)₹546.00

-

OG A5 300GSM White Sheet (Set of 15)₹375.00

Hemp Cordages

Hemp ropes are among the oldest rope fibres known to man. From the age of classic sail to the present times, hemp has remained a soft, supple, and strong rope versatile for use in decorating, design, marine, sports, and theatrical applications. A typical hemp rope has the following process.

We separate hemp fibres. Then cut them into lengths approximately twice as long as the desired length. The aim is to obtain a bundle of fibres that are half the size of the desired diameter.

The bundles are folded in half and secured by a dowel rod. The next step is to smoothen the fibres of the bundles along the length of the cord. Following this, we divide the bundles into two parts. Each bundle is rotated clockwise until the cord begins to kink and loop.

Then, we twist the two cords together wrapping one over the other in a counter-clockwise motion. On securing the ends with overhand knots beginning with the end in the maker’s hand, the rope is slipped off the dowel rod and tied.

Hemp Biofuel

Hemp can provide mankind with two types of fuels—hemp biodiesel and hemp ethanol/methanol. The process of pressing hemp seeds to extract oil produces hemp-based biodiesel.

CBD

The extraction of the cannabinoid CBD is perhaps currently the widest use of hemp. With more and more research revealing the many benefits of CBD, the extraction of CBD-based products from hemp is gaining traction.

CBD oil extracted from hemp is used for its medicinal and therapeutic properties. It can be used directly, in the form of oil or converted into a range of other CBD products such as gummies, edibles, drinks, and balms/lotions.

-

India Hemp Organics CannaBliss Arthritis Relief- CBD Oil (100ml)₹1,399.00

-

Zero CBD Blue Dream 15mg Broad Spectrum CBD Gummies (4 Pcs)₹400.00 – ₹7,000.00

-

Neet 300mg Broad Spectrum Vijaya Tailam CBD 30ml₹1,999.00

-

Cure By Design Organic Hemp Balm 2000 mg CBD (50 gms)₹2,500.00

-

Zero CBD Grand Daddy Purple 15mg Broad Spectrum CBD Gummies (4 Pcs)₹400.00 – ₹7,000.00

-

Cure By Design Hemp Oil for Pets – 500mg CBD (30ml)From: ₹2,000.00

-

India Hemp Organics CannaBliss Arthritis Relief- CBD Oil (50ml)₹999.00

-

Product on saleBroad Spectrum CBD Drops₹1,999.00 – ₹9,999.00

-

Cannabryl Full Spectrum Vijaya Extract For Dogs, 1500mg, CBD-THC Balanced, 30ml₹4,500.00

-

Product on saleAndyou – Vibe&U Mood Uplift Gummies (200mg CBD + terpenes for good vibes), Orange Flavour, 10 GummiesOriginal price was: ₹1,499.00.₹1,320.00Current price is: ₹1,320.00.